Top 10 Fabrics for Fashion Streetwear Work Pants

Fashion streetwear work pants are a blend of functional workwear and stylish streetwear. They need to be practical and fashionable. They need to be durable, comfortable, and stylish. How do you choose the right fabric to meet these demands? Here are the top 10 fabrics suitable for fashion streetwear work pants.

1. Cotton

Characteristics and Advantages:

Cotton is a natural fiber made from 100% cotton or cotton blends. It’s breathable and has high moisture absorption. It’s comfortable to wear and suitable for various climate conditions, especially hot summer days. The common fabric density is 20×16 (warp and weft yarn density)/16×12. The weight ranges from 200-300 g/m². Cotton is soft and has a natural texture, which makes it very comfortable for everyday wear.

Disadvantages:

Pure cotton wrinkles easily and has lower abrasion resistance compared to synthetic fibers, which may shorten its lifespan. Therefore, cotton work pants often require extra care, such as regular ironing and avoiding excessive wear, to maintain their best condition.

2. Polyester-Cotton Blend

Characteristics and Advantages:

Polyester-cotton blend fabric combines the durability of polyester with the comfort of cotton. The common ratio is 65% polyester and 35% cotton. This blend is easy to wash and quick to dry. It resists wrinkling, which is great for busy people and work environments requiring frequent washing. The fabric density is typically 20×16. The weight ranges from 180-280 g/m².

Disadvantages:

None significant, but the blend may not offer the same level of comfort as pure cotton.

3. Polyester

Characteristics and Advantages:

Polyester fabric is made from 100% polyester fibers. It’s durable, waterproof, oil-resistant, and has strong wrinkle resistance. The fabric density is typically 30×30. The weight ranges from 150-250 g/m². Polyester is easy to wash and quick to dry. It resists chemicals and UV rays. It’s suitable for outdoor and industrial environments.

Disadvantages:

Polyester doesn’t breathe well, which can make it feel hot in high temperatures.

4. Nylon

Characteristics and Advantages:

Nylon fabric is known for its high strength, abrasion resistance, and chemical resistance. It’s a popular choice for work pants that require exceptional durability. The fabric density is typically 40×40. The weight ranges from 160-240 g/m². Nylon is waterproof, oil-resistant, and resists UV rays and mildew. It performs well in outdoor work environments.

Disadvantages:

Nylon isn’t as comfortable as cotton, but modern blends improve breathability and feel.

5. Oxford

Characteristics and Advantages:

Oxford cloth is usually made of polyester or nylon blended with cotton. It has high wear resistance and is waterproof. The density of Oxford cloth is usually 20×20, and the weight is between 200-400 g/m². Oxford cloth has excellent tear resistance and a relatively stiff texture with a slight sheen.

Disadvantages:

May feel stiff compared to other fabrics, requiring break-in time for comfort.

6. Twill

Characteristics and Advantages:

Twill fabric is usually made of cotton or polyester-cotton blended fabric (100% cotton, CVC 60/40, TC 65/35). It has a distinct texture and is highly wear-resistant. The density of twill fabric is usually 21×21, and the weight is between 190-300 g/m². The twill weave structure enhances strength, durability, and provides some elasticity.

Disadvantages:

May require special care to maintain texture and appearance.

7. Canvas

Characteristics and Advantages:

Canvas is a thick and durable fabric, usually made of cotton or cotton-polyester blended fabric. It is known for its high strength and abrasion resistance. The density of canvas is usually 10×10, and the weight is between 200-400 g/m². Canvas is excellent for work pants and bags due to its durability and tear resistance.

Disadvantages:

Can be heavy and stiff, requiring break-in for comfort.

8. Denim

Characteristics and Advantages:

Denim is usually made of cotton or cotton blended fabric, sometimes containing a small amount of polyester or elastane. The common density of denim is usually 3×1 twill, and the weight is between 300-450 g/m². Denim is durable, thick, breathable, and moisture-absorbent. It’s a classic fabric for work pants and casual pants.

Disadvantages:

Denim can be heavy and may shrink if not properly treated.

9. Stretch Fabric

Characteristics and Advantages:

Stretch fabric is usually made of cotton, polyester, or nylon blended with elastic fibers such as spandex or Lycra. Common ratios are 97% cotton 3% spandex, and 80% nylon 20% spandex. The density of stretch fabric is usually 20×16+70D, and the weight is between 180-300 g/m². Stretch fabric is known for its high elasticity and good comfort.

Disadvantages:

May lack sufficient strength and stability when used alone.

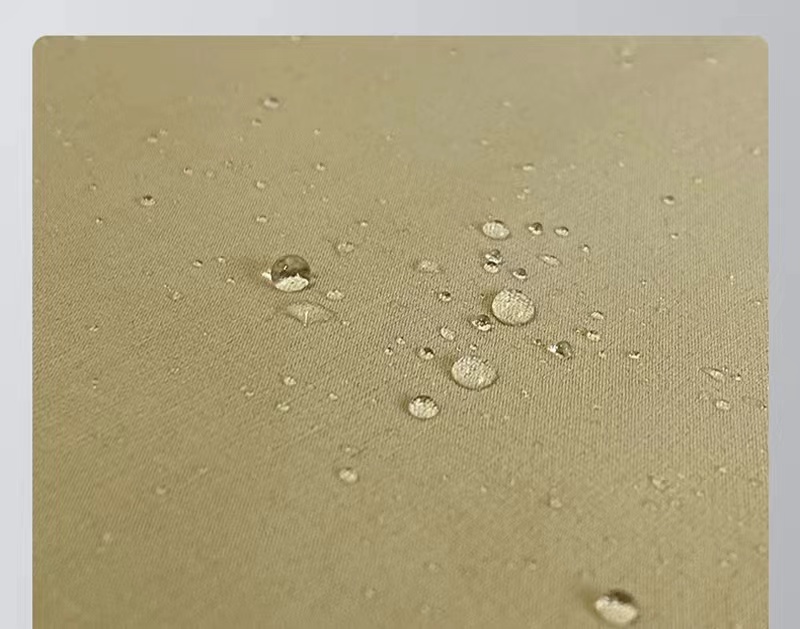

10. Post-processing Treatments

Post-processing treatments can enhance all the fabrics listed above to increase their functionality. Common treatments include:

- Waterproof: Coating or impregnating the fabric with waterproof agents to create a hydrophobic layer on the surface.

- Stain-resistant: Treating the fabric with stain-resistant agents to repel dust and stains.

- Antimicrobial: Adding antimicrobial agents to inhibit bacteria growth.

- UV-resistant: Adding UV-resistant agents to increase the fabric’s ability to block UV rays.

Choosing the right fabrics and post-processing treatments allows you to create work pants that are both durable and stylish, meeting the needs of different people in various environments.

100% COTTON FABRIC

100% COTTON FABRIC COTTON STRETCH FABRIC

COTTON STRETCH FABRIC POLYESTER/COTTON FABRIC

POLYESTER/COTTON FABRIC OTHERS FABRIC

OTHERS FABRIC