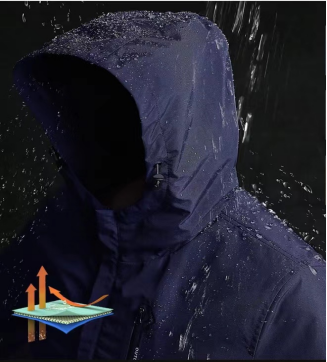

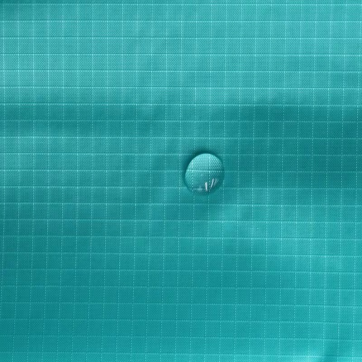

Q1: What is PU Coating?

A1: PU (Polyurethane) coating is a protective layer applied to fabrics to enhance their performance characteristics. You apply a polymer to the fabric that is flexible, strong, and durable. PU coatings can provide a range of benefits, including permanent water resistance, durability, waterproof and improved aesthetic appeal and handfeel.

Q2: What are the primary functions of PU coating?

A2: PU coating does several things. It makes fabrics water-resistant and waterproof, so you can use them for outdoor gear and rainwear. It increases the fabric’s resistance to abrasion, tearing, and wear and tear. Even though it makes the fabric tougher, it remains flexible and easy to manipulate. PU-coated fabrics resist oils, chemicals, and stains, so they’re easier to clean. The coating can add a glossy or matte finish. You can dye or print it to create different designs and colors.

Q3: Where are PU-coated fabrics commonly used?

A3: You’ll find PU-coated fabrics in a wide range of applications. These include fashion and apparel for outerwear like jackets, coats, and rainwear. You’ll also find them in outdoor and sports gear such as tents, backpacks, and athletic shoes because they’re durable and resist environmental elements. They’re used in industrial applications like conveyor belts, protective covers, and tarpaulins. You’ll find them in automotive and marine applications in upholstery, convertible tops, and protective covers. They’re also used in home furnishings, where they’re popular in upholstery and curtains because they’re easy to clean and resist spills and stains.

Q4: What types of fabrics can be coated with PU?

A4: You can coat a variety of fabrics with PU. These include polyester, which becomes highly water-resistant and durable with PU coating and is commonly used for outdoor gear and sportswear. Nylon is another fabric that benefits from PU. It’s often used in jackets, backpacks, and tents. PU coating makes it even stronger. You can coat cotton with PU to make it water-resistant and more durable. This makes it suitable for rainwear and workwear. You can also coat poly cotton blends with PU. These fabrics combine natural and synthetic fibers and benefit from PU coating to improve their overall performance. Finally, you can coat leather and faux leather with PU. This adds a protective layer and enhances durability and appearance.

Q5: How is PU coating applied to fabrics?

A5: You apply PU coating to fabrics in several steps. First, you clean and prep the fabric to ensure a smooth and even coating. Then, you apply the coating using methods like knife coating, roller coating, or spray coating. The method you choose depends on the desired thickness and properties. Next, you cure the coated fabric by applying heat. This bonds the coating firmly with the fabric. Finally, you may perform additional processes like embossing, printing, or dyeing to enhance the fabric’s appearance and functionality.

Q6: Is PU coating breathable?

A6: PU-coated fabrics can vary in breathability. In general, PU coatings are less breathable than untreated fabrics because the coating creates a barrier that can limit airflow. However, advancements in PU technology have led to the development of microporous PU coatings, which allow for some level of breathability while still providing water resistance. These breathable PU coatings are particularly useful in applications such as activewear and outdoor gear, where both breathability and water resistance are important. For maximum breathability, you can look for fabrics that combine PU with other breathable materials or use innovative techniques to ensure a balance between protection and airflow.

Q7: What environmental considerations are associated with PU-coated fabrics?

A7: PU-coated fabrics have environmental impacts, primarily due to the use of chemicals in PU production, which can be harmful if not managed properly, and the non-biodegradability of PU-coated fabrics, posing disposal challenges. However, the industry is advancing towards more sustainable practices. Innovations in bio-based polyurethanes and recycling technologies are helping to reduce environmental impacts.

Q8: How can I care for PU-coated fabrics?

A8: Proper care can extend the lifespan of PU-coated fabrics. Cleaning should involve wiping with a damp cloth and using mild soap for stubborn stains, avoiding harsh chemicals. Storage should be in a cool, dry place away from direct sunlight to prevent UV degradation. Small tears can be repaired with specialized adhesives or repair kits designed for coated fabrics.

Q9: Are there eco-friendly alternatives to traditional PU coatings?

A9: Yes, there are eco-friendly alternatives, including bio-based polyurethanes made from renewable resources, which reduce reliance on petroleum-based chemicals, and recycling initiatives where some manufacturers are developing methods to recycle PU-coated fabrics, minimizing waste and environmental impact.

Q10: What are the advancements in PU coating technology?

A10: Recent advancements include the development of coatings that offer greater resistance to extreme conditions, innovations that maintain flexibility without compromising durability, and an increasing focus on sustainable and biodegradable coatings.

Q11: How does PU coating compare to other types of fabric coatings?

A11: PU coating offers unique advantages, including versatility, making it suitable for a wide range of applications compared to some other coatings; performance, providing a balance of durability, flexibility, and aesthetic options; and cost-effectiveness, as it is generally more affordable than high-end alternatives like PTFE (Teflon) coatings.

Q12: What are the limitations of PU-coated fabrics?

A12: While PU-coated fabrics are highly beneficial, they have some limitations. They can degrade at high temperatures, limiting their use in extreme conditions. They may not be as breathable as fabrics without coating, which can be a drawback for certain apparel applications. Additionally, they are not biodegradable and involve chemical use, which poses environmental challenges.

Q13: Can PU coatings be customized for specific applications?

A13: Yes, PU coatings can be tailored to meet specific requirements. By adjusting the formulation and application process, manufacturers can create coatings with varying levels of water resistance, flexibility, and breathability. For instance, a PU coating for outdoor gear might prioritize water resistance and durability, while a coating for fashion apparel might focus on aesthetic qualities and softness. This customization ensures that PU-coated fabrics can meet the diverse needs of different industries and applications.

Conclusion

PU coating significantly enhances fabric performance, offering water resistance, durability, and flexibility for various applications. While there are environmental considerations, advancements in sustainable practices are addressing these concerns. By understanding the properties, care requirements, and innovations in PU-coated fabrics, you can make informed decisions to maximize benefits and sustainability.

100% COTTON FABRIC

100% COTTON FABRIC COTTON STRETCH FABRIC

COTTON STRETCH FABRIC POLYESTER/COTTON FABRIC

POLYESTER/COTTON FABRIC OTHERS FABRIC

OTHERS FABRIC