Australia is famous for its unique and often extreme working conditions.

From the blistering heat of the outback to the unpredictable and sometimes harsh weather of coastal regions, Australian workers face a variety of environmental challenges. These diverse conditions create a high demand for workwear fabrics that are not only durable and comfortable but also capable of providing the necessary protection and performance for a wide range of industries.

Whether it’s the mining industry in Western Australia, the agricultural sector in New South Wales, or the construction sites in bustling cities like Sydney and Melbourne, workers need workwear that can stand up to the rigors of their daily work.

High-quality fabrics are essential in ensuring that workwear can endure heavy use, provide comfort for long hours, and, most importantly, keep workers safe from various hazards.

In this article, I’ll delve into the hot sale workwear fabrics in the Australian market, highlighting the top choices that meet these stringent requirements.

I’ll explore the unique features that make these fabrics popular among Australian businesses, as well as the essential test standards that ensure they perform as needed in demanding work environments. By understanding the qualities and certifications of these fabrics, you’ll be able to make informed decisions when selecting workwear, ensuring your workforce is equipped with the best possible gear for their safety and productivity.

The Importance of Quality Workwear Fabrics

In Australia, workwear is more than just a uniform. It’s a critical component of workplace safety and efficiency. High-quality fabrics not only protect workers from environmental hazards but also enhance comfort, which can significantly impact productivity. As such, businesses are increasingly investing in top-notch workwear fabrics that offer superior performance, durability, and compliance with safety standards.

Top-Selling Workwear Fabrics in Australia

1. Heavy-Duty Cotton Drill (With UPF50+)

Cotton drill is a heavyweight fabric known for its durability and comfort, making it a staple in the Australian workwear market.

Here are some popular fabric as below:

1)WORK SHIRTS:

150gsm/190gsm PRESHRUNK COTTON DRILL FABRIC & 150gsm/170gsm

PRESHRUNK COTTON RIPSTOP FABRIC.

2) WORK TROUSERS:

190gsm/240gsm PRESHRUNK COTTON DRILL FABRIC &200gsm

PRESHRUNK COTTON RIPSTOP FABRIC.

3) Bib Pants & Coveralls:

190gsm/240gsm/310gsm PRESHRUNK COTTON DRILL FABRIC &240gsm

PRESHRUNK POLY/COTTON DRILL FABRIC.

Key Features:

1)Breathability: Ideal for hot climates as it allows air circulation, keeping workers cool.

2)Durability: Resistant to wear and tear, making it suitable for demanding environments.

3)Comfort: Soft and comfortable for long hours of wear.

Applications: Construction, mining, agriculture, and other heavy-duty industries.

Relevant Standards:

1)AS/NZS 1906.4: High-visibility materials for safety garments.

2)OEKO-TEX® Standard 100: Certification ensuring the fabric is free from harmful substances.

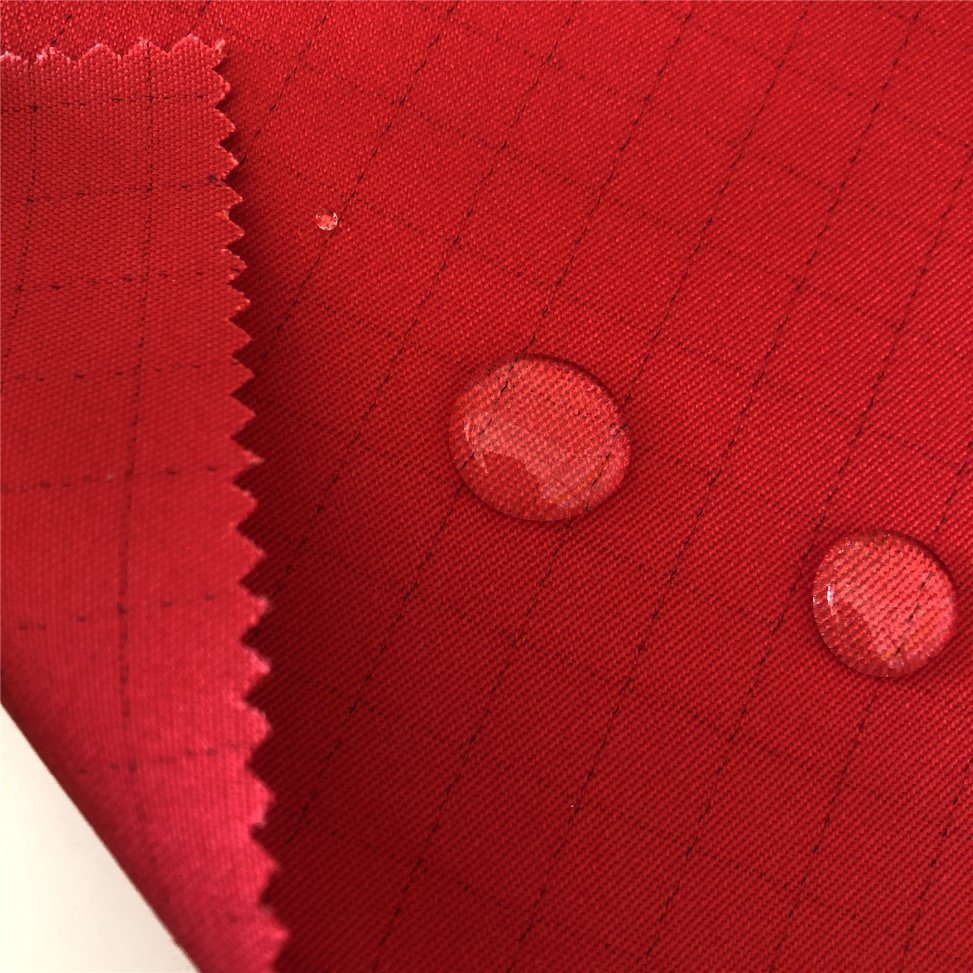

2. Flame-Resistant Cotton/Nylon Blend OR 100% Cotton

You need flame-resistant (FR) treatment on your cotton/nylon blend or 100%cotton fabric. This is the fabric you need if you’re going to be around fire.

Key Features:

1)Flame Resistance: You need this to protect you from flash fires and electric arcs.

2)Durability: The nylon makes the fabric stronger and last longer.

3)Comfort: You need to be comfortable while you’re being protected.

4)Applications: Oil and gas, firefighting, welding, electrical work.

Relevant Standards:

1)NFPA 2112: Standard on flame-resistant clothing for protection against flash fire.

2)ISO 11612: Protective clothing against heat and flame.

3. Hi-Vis Polyester/Cotton Blend

You need high-visibility (hi-vis) fabrics if you’re going to be working in low-light or high-traffic areas. The most common hi-vis fabric is 240-250gsm 55% polyester 45% cotton.

Key Features:

1)High Visibility: You need to be seen by others.

2)Durability: You need the fabric to last, but you don’t want to sacrifice comfort.

3)UV Protection: Protected from the sun if you’re working outside.

4)Applications: Road construction, warehousing, logistics, outdoor maintenance.

Relevant Standards:

1)AS/NZS 4602.1: High-visibility safety garments for day and night use.

2)EN ISO 20471: High-visibility clothing for increased visibility.

4. Anti-Static Fabrics

You need anti-static fabrics if you’re going to be around static electricity. This is important if you’re working with electronics or in an explosive environment.

Key Features:

1)Static Dissipation: You need this to prevent static electricity from building up.

2)Durability: You need the fabric to last in a tough environment.

3)Comfort: You need to be comfortable while you’re being protected.

4)Applications: Electronics manufacturing, chemical handling, explosives handling.

Relevant Standards:

1)EN 1149-5: Protective clothing with electrostatic properties.

2)IEC 61340-5-1: Protection of electronic devices from electrostatic phenomena.

It’s important to know the testing methods and standards that apply to workwear fabrics. Here are some of the key ones: By following these testing methods and standards, you can make sure the fabrics you’re using for your workwear are going to protect you and perform for you.

100% COTTON FABRIC

100% COTTON FABRIC COTTON STRETCH FABRIC

COTTON STRETCH FABRIC POLYESTER/COTTON FABRIC

POLYESTER/COTTON FABRIC OTHERS FABRIC

OTHERS FABRIC