In 2024, we’re seeing some exciting developments in the industrial workwear fabric market. The market is being driven by innovation, sustainability, and a growing emphasis on worker safety and comfort. Companies are recognizing the importance of high-quality workwear to improve productivity and protect their workforce. Here are the top trends in industrial workwear fabric for 2024.

1. Sustainable and Eco-Friendly Fabrics

As environmental concerns continue to grow, the demand for sustainable and eco-friendly workwear fabrics is increasing. Fabric manufacturers are now producing fabrics made from recycled materials, organic cotton, and other sustainable sources.

Key Points:

1) Recycled Materials: Many industrial fabrics are now made from recycled polyester and other reclaimed fibers, reducing waste and promoting circular economy practices.

2) Organic and Natural Fibers: The use of organic cotton, hemp, and bamboo is on the rise, offering biodegradable options that are gentle on the environment.

3) Eco-Friendly Dyes and Finishes: Environmentally friendly dyeing processes and non-toxic finishes are becoming standard.

2. Enhanced Durability and Performance

Durability is a critical factor in industrial workwear. In 2024, we’re seeing innovations focused on extending the lifespan of fabrics while maintaining performance in extreme conditions. For example, canvas and ripstop fabric are great choices.

Key Points:

1) Abrasion and Tear Resistance: Advanced weaving techniques and stronger synthetic fibers like aramid and ultra-high-molecularweight polyethylene (UHMWPE) are being used to create fabrics that can withstand heavy wear and tear.

2) Moisture-Wicking and Breathability: Modern fabrics incorporate moisture-wicking technologies and breathable membranes to provide comfort in high-temperature and physically demanding environments.

3) Stain and Water Resistance: Enhanced treatments provide superior resistance to stains, oils, and water, making workwear easier to maintain and keeping workers clean and dry.

3. Customization and Personalization

In 2024, we’re seeing a trend toward customized and personalized workwear that meets the specific needs of different industries and individual workers. Companies are realizing that one-size-fits-all solutions aren’t always the best, and there’s a growing demand for tailored workwear that improves safety and performance.

Key Points:

1) Tailored Fit: Custom-fit workwear improves comfort and mobility, reducing the risk of accidents and improving productivity. By providing workers with clothing that fits them properly, companies can ensure they’re not hindered by ill-fitting garments.

2) Branded Workwear: Personalized workwear with company logos and colors helps build brand identity and creates a sense of unity among workers. It also makes it easier to identify employees onsite, which can improve security and team coordination.

3) Industry-Specific Solutions: We’re seeing more fabrics and designs tailored to specific industries. Here are a few examples:

a) 100% Cotton Fabric:Use Case:Ideal for workers in cooler environments or those not exposed to hazardous conditions, such as logistics and warehousing.

Benefits: Cotton is breathable, comfortable, and soft, making it suitable for long hours of wear. It’s also less likely to cause skin irritations.Certifications: OEKO-TEX® Standard 100, ensuring the fabric is free from harmful substances.

b) Cotton/Nylon Fabric with Flame-Resistant (FR) Treatment

Use Case: Perfect for firefighters, welders, and workers in the oil and gas industry who are exposed to flames and high temperatures.

Benefits: The blend of cotton and nylon offers a balance of comfort and durability. The FR treatment provides critical protection against burns.

Certifications: NFPA 2112 (Standard on Flame-Resistant Clothing for Protection of Industrial Personnel Against Flash Fire) and ISO 11612 (Protective Clothing Against Heat and Flame).

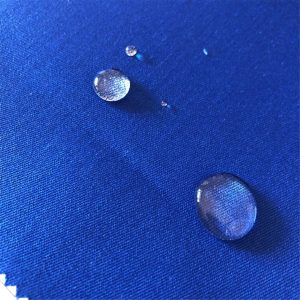

c) Waterproof Teflon-Coated Fabric

Use Case: Ideal for outdoor workers who need protection from rain and wet conditions, such as construction and landscaping.

Benefits: The Teflon coating provides water resistance, keeping workers dry and comfortable.

By offering these industry-specific, customized solutions, businesses can ensure their workers have the best possible protection and comfort, tailored to their unique job requirements. This not only improves safety and performance but also demonstrates a commitment to employee well-being, fostering a positive work environment.

4. Compliance and Certification

You need to make sure the industrial workwear fabrics you buy meet industry standards and certifications so you know they’re safe and good quality.

Here’s what you need to know:

1)ISO and ANSI Standards: You need to make sure the fabrics you buy meet international standards like ISO 11612 for heat and flame

protection and EN20471 for high-visibility workwear fabric.

2)Certification Labels: You want to look for labels like OEKO-TEX® Standard 100 and Global Organic Textile Standard (GOTS) to make sure the fabric is safe and made responsibly.

3)Third-Party Testing: You want to make sure the fabric you buy has been tested and certified by an independent lab to make sure it meets the standards you need it to meet.

Conclusion

The industrial workwear fabric industry is changing fast. People are coming up with new ideas, trying to make things more sustainable,and trying to make things safer and more comfortable for workers. If you want to keep up, you need to pay attention to what’s going on. If you want to stay ahead, you need to be the one coming up with the new ideas. As we move into 2024, the industry is going to keep changing. You need to keep up if you want to stay in the game.

100% COTTON FABRIC

100% COTTON FABRIC COTTON STRETCH FABRIC

COTTON STRETCH FABRIC POLYESTER/COTTON FABRIC

POLYESTER/COTTON FABRIC OTHERS FABRIC

OTHERS FABRIC