Specialized Fabrics for Safety, Education, and Performance Wear

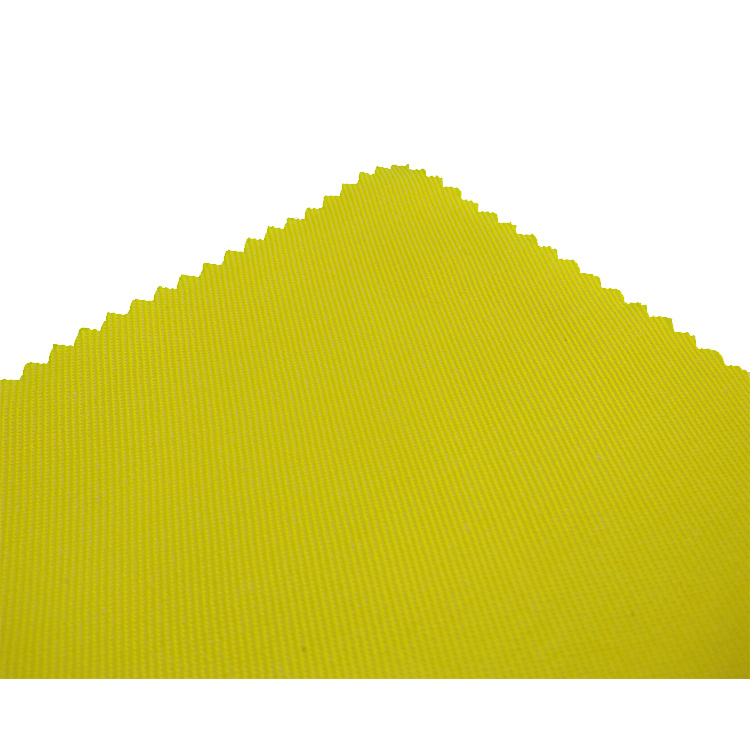

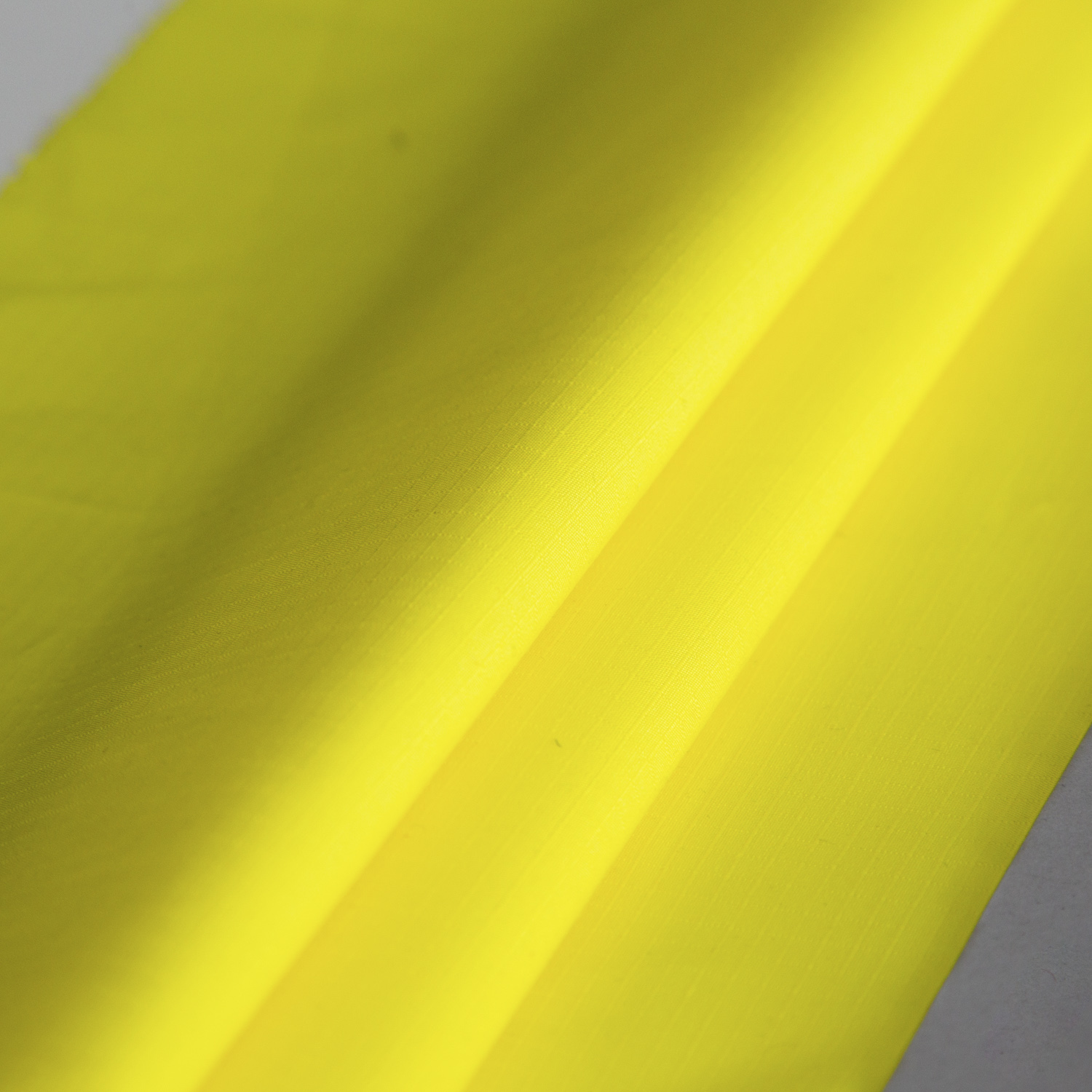

Fluorescent Fabrics: Our fluorescent fabrics, composed of 55% cotton and 45% polyester, or polyester-cotton stretch blends, meet the stringent EN20471 standards for high visibility. These fabrics are ideal for safety wear, ensuring maximum visibility and safety in low-light conditions.

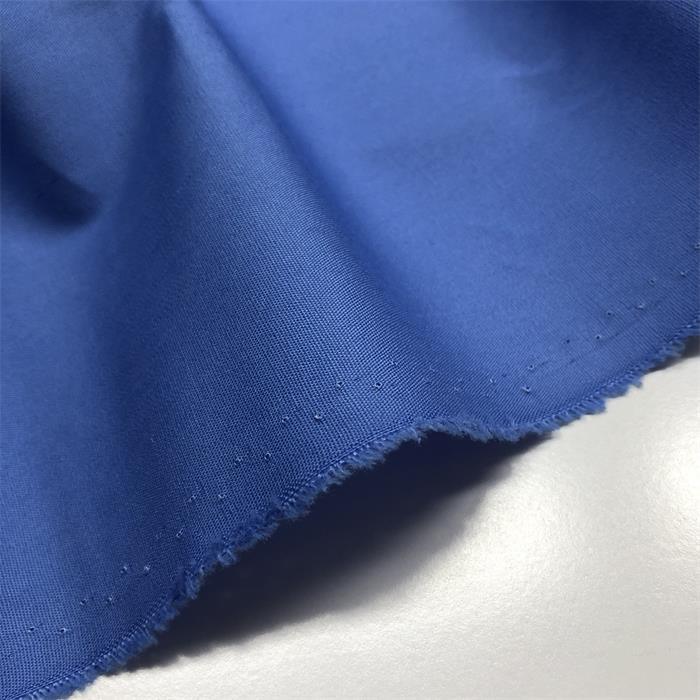

T/R Blends: Our T/R blend fabrics, consisting of 65% polyester and 35% viscose, are perfect for school uniforms. They offer a balance of durability and comfort, making them ideal for daily wear in educational settings. The fabric’s smooth texture and excellent drape provide a professional appearance.

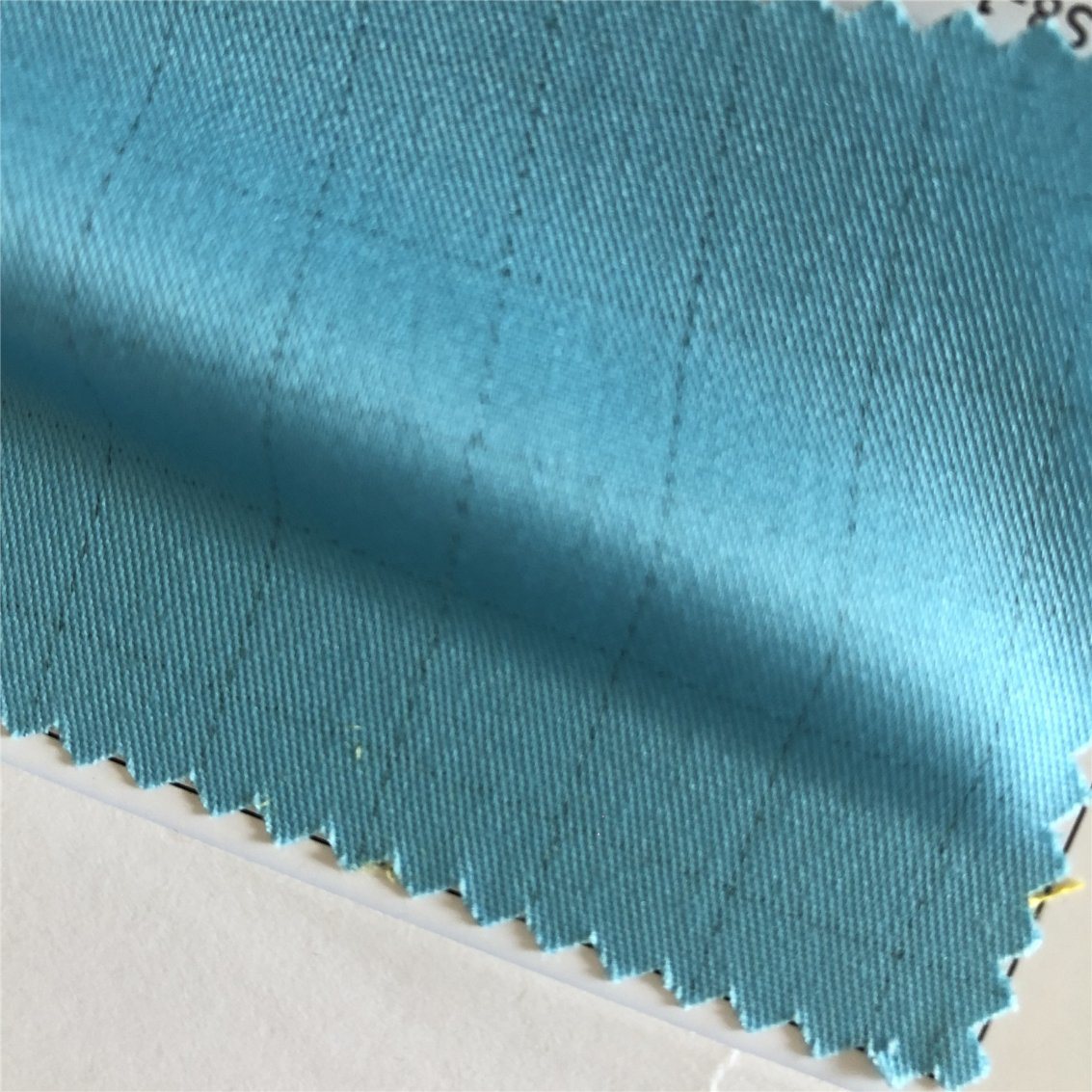

Polyester/Cotton Stretch Blends: Our polyester/cotton stretch blends include compositions like 65% polyester, 32% cotton, and 3% spandex, as well as 60% cotton, 38% polyester, and 2% spandex. These fabrics are designed for flexibility and comfort, making them suitable for various applications including casual wear, workwear, and sportswear. The added spandex ensures stretchability, providing ease of movement and superior fit.

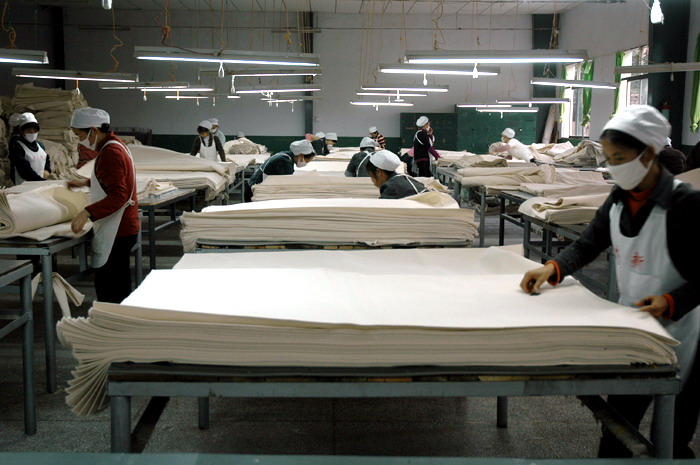

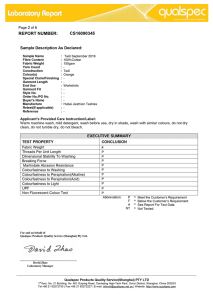

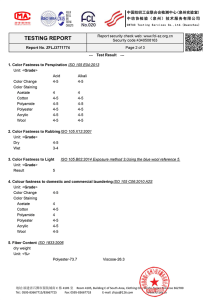

At Hubei Jiezhixin Textiles, we are committed to offering high-quality fabrics tailored to meet specific industry requirements. Our specialty fabrics are rigorously tested and certified, ensuring they deliver exceptional performance and durability. Choose us for your next project and experience the innovation and quality of our specialty fabric range.

100% COTTON FABRIC

100% COTTON FABRIC COTTON STRETCH FABRIC

COTTON STRETCH FABRIC POLYESTER/COTTON FABRIC

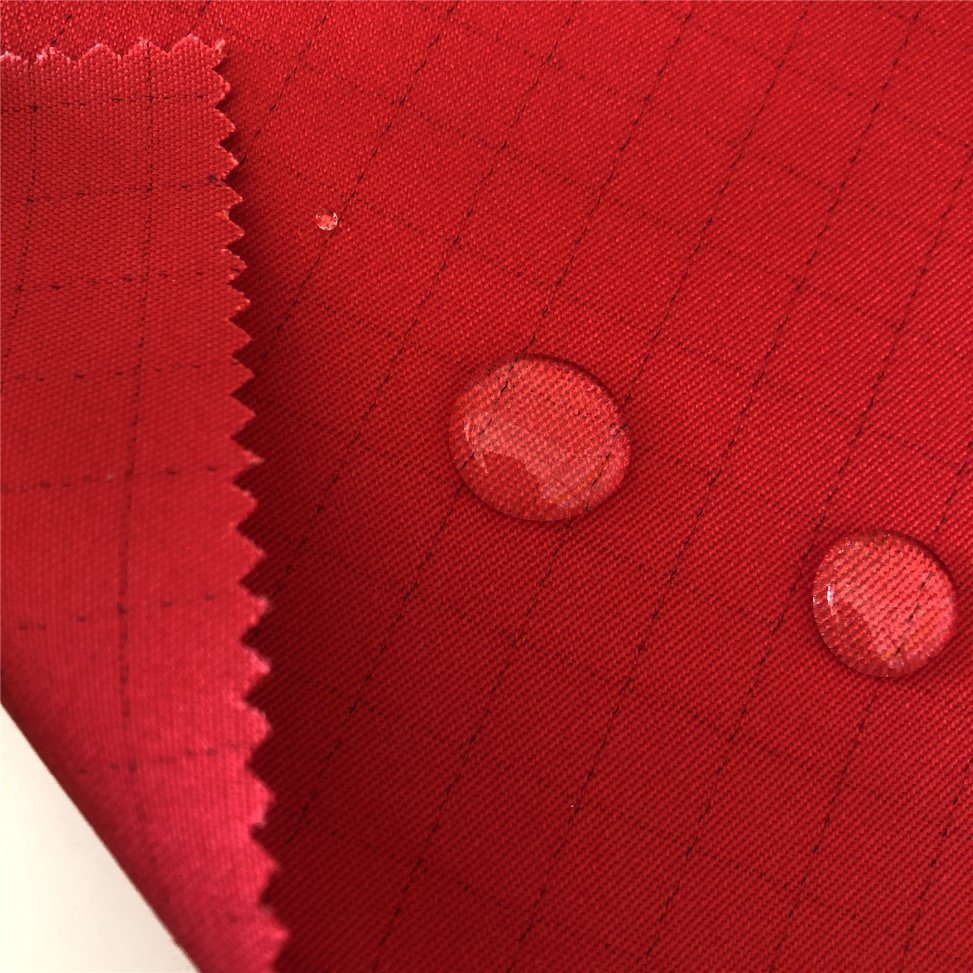

POLYESTER/COTTON FABRIC OTHERS FABRIC

OTHERS FABRIC